- Mon - Fri:9:00 - 17:00

- kuoan@kuoan.com.tw

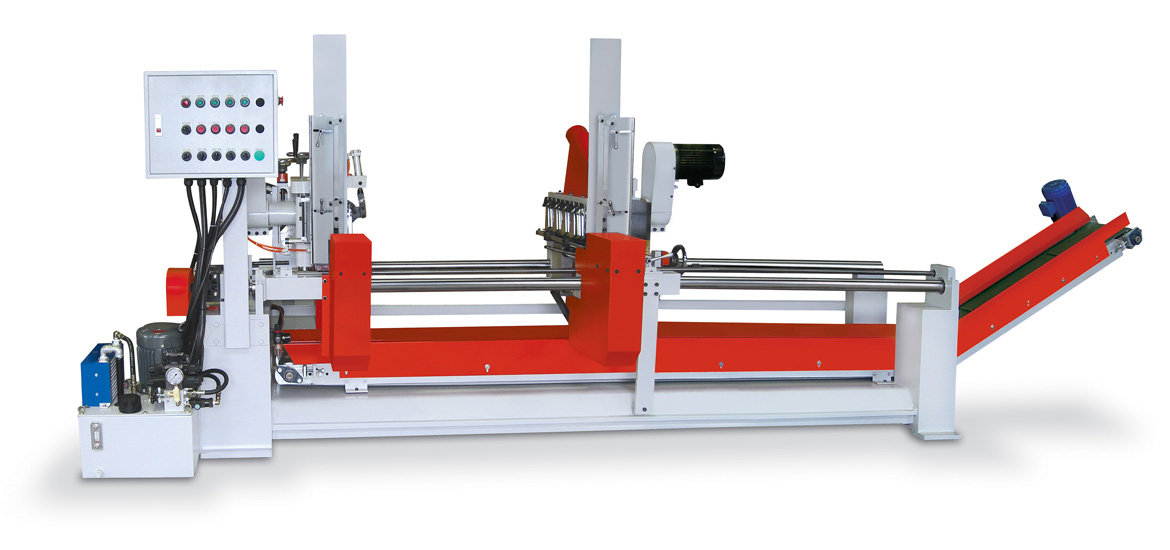

Full automatic double end cut-off machine

KA-2200

- The machine could link up the four-side planer& moulder with the front feeding area. Cuts the length of material first , then working with four-side planer & moulder for processing and shaping.

- The machine is equipped with automatic waste wood material conveyor automatically transfer the cutting material to the return cover.

- KA-2200 combine with four-side planer & moulder to form systems, it may reduce labor work and transport process, promotion up factory space efficiency.

- KA-2200 to cut the length of material first, and setup the fixed length, to be allowed directly transmission to four side planer & moulder to link continues process. Horizontal steel wheel transport by hydraulic driving motor,the working speed is for 40m/min.

- KA-2200 combine with automatic waste material conveyer, automatically transports cutting material to the recycling car.

| Range of workpiece length | 250-2200mm |

|---|---|

| Range of workpiece width | 150mm |

| Range of workpiece thickness | 20-70mm |

| Spindle motor | 3HP*2 |

| Spindle speed | 3000 rpm/min |

| Spindle diameter | 1"(25.4mm) |

| Saw blade dia. | 14"(355.6mm) |

| Table height | 900mm |

| Hydraulic pump motor |

3HP |

| Waste material conveyer motor | 1HP |

| Machine size (L*W*H) | 5500*1500*1800mm |

| Packing size (L*W*H) | 5600*1600*2000mm |

| Net weight | 1650kgs |

| Gross weight | 1800kgs |